Our planet has changed so much in the last two hundred years. Human activities are the main reason for this drastic change.

Nature has protected our planet with the ozone layer. This ozone layer is present in the outer atmosphere and prevents the harmful radiation from the sun from entering our planet. Due to pollution and excessive use of chlorofluorocarbons, the ozone layer has developed a hole. Now, our shield is compromised, and harmful radiation enters our atmosphere.

There is a strong need to control activities that are damaging our atmosphere. One of the ways is to limit the use of chlorofluorocarbons, which are used in air conditioning systems and other home appliances. We can do this by making our homes energy efficient. This means maintaining our home’s internal environment, including temperature, without excessive use of energy. This can be done by taking several measures, like retrofitting, using low-E coating windows, and making our home net-zero.

In this blog, we will focus on low-E glass. Discuss their types and benefits. Let’s promote eco-friendly ways to stay comfortable and protect our planet for our future generation.

What Is Low-E Glass?

Low E-coating is a thin metallic layer usually of indium tin oxide or silver applied to the glass surface. These coatings are made to control heat transfer.

The main purpose of low E-coatings is to reflect sunlight of longer wavelength, usually infrared radiation, which serves to heat the home. At the same time, they let the short-wave solar energy pass through. In winter, sunlight can still warm your home. The heat inside stays trapped. This reduces the need for heating systems. In summer, the coating blocks excess solar heat from entering the home. This makes your air conditioning system work less.

As a result, homes with Low-E windows are more comfortable all year. They also have lower energy bills. There is less reliance on heating and cooling systems.

Read More: Navigating Winter: Choosing Between Double-Pane and Triple-Pane Windows

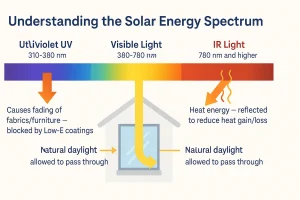

Understanding the Solar Energy Spectrum

To understand the working of Low E-coatings, it’s important to understand the composition of the solar spectrum. The solar spectrum consists of Ultraviolet (UV) light, visible light and infrared (IR) light. All these components of the spectrum have different wavelengths and heating properties.

- Ultraviolet light rays occupy the wavelength of 310-380 nanometers. These wavelengths, when enter the interior of the home, cause fabrics, wall coverings, and interior to fade away.

- Visible light occupies the part of the spectrum between wavelengths from 380-780 nanometers.

- Infrared light rays have wavelengths of 780 nanometers and higher. It is transmitted as heat that warms the interior of homes and buildings.

So low E-coating blocks UV radiation (310-380 nm) from entering homes and buildings to protect furniture, fabrics, and flooring from fading. They also block Infrared rays (780 nm – 1 mm) to reduce unwanted heat gain in summer and heat loss in winter. Only visible light waves (≈380–780 nm) are allowed to pass to keep rooms bright with natural daylight.

The Role of Emissivity in Windows

The ability of the glass or any other material to radiate and re-radiate energy is known as its emissivity, and thus highly reflective materials generally have a low emissivity. The ability to lower the emissivity of the glass surfaces in a window improves its insulating properties.

When light or heat is absorbed by glass, it is either reflected or radiated by the glass surface. Glasses that highly reflect light or heat have low emissivity. Usually, light and shiny surfaces reflect most of the light and therefore have low emissivity. Whereas dark and dull surfaces perform maximum absorption and have higher emissivity.

Radiant energy is one of the important ways heat transfer occurs through windows. Reducing the emissivity of the window glass surfaces improves its insulating properties. For example, uncoated glass has an emissivity of 0.84, while properly coated glass has an emissivity of 0.02.

How Do Low-E Coatings Work?

With normal uncoated glass windows, much of the solar radiation passes through. This radiated heat warms the interior of the home above the optimum comfortable temperature. This is undesirable, especially in summer. Moreover, the heat from the interior of the home also escapes easily via these uncoated windows. This reduces the interior temperature below the optimum and is undesirable, especially in winter.

In ideal situations, windows must prevent heat from entering homes from the hot exterior environment in summer. They must also prevent the warmth of the interior from escaping in winter. The ability of the glass or any other material to radiate and re-radiate energy is known as its emissivity, and thus, highly reflective materials generally have a low emissivity

Low-E-coating glass has a thin, transparent coating of low-emissive material that reflects the infrared radiation. This prevents heat transfer between the inside and outside environments.

To understand the working of low-emissive windows, we first understand the process of thermal equilibrium, to explain why uncoated windows allow heat to pass through them. In this phenomenon, when two surfaces are in contact with each other and have different temperatures, heat flows between them until both attain the same temperature.

In normal, uncoated windows, the heat of the interior heats the inner side of the window. As the temperature of the outer side is different so heat flow occurs. And the heat from inside transfers to outside, thereby decreasing the interior temperature. This makes homes and buildings less efficient. The opposite situation happens in summer, when heat and infrared rays from the outside enter the homes and buildings.

In the case of coated windows, when the interior heat energy tries to escape to the colder outside during the winter, the low-e coating reflects the heat to the inside because of its low emissive nature. This reduces the radiant heat loss through the glass. The reverse happens during the summer.

Types of Low-E Coatings

There are two types of Low-E coating glass. Let’s discuss them!

Passive Low-E Coatings

Passive Low-E coatings are made through a process called pyrolytic coating. These coatings usually have a layer of indium tin oxide. This material has low emissivity. Although indium tin oxide coating has low emissivity yet it still allows shorter wavelength radiations to pass through it. So, passive Low-E coatings are best for cold climates. They let some of the sun’s heat, usually low-wavelength radiation, enter the home in winter. At the same time, they reflect indoor heat inside because heat radiations generated by appliances and the interior of the home have a higher wavelength. This helps keep the house warmer for a longer time.

Because they let in more solar energy, their insulating values are not the highest. However, they are a smart choice for homes that use passive solar heating. More light and warmth enter the home. This reduces the need for heating systems.

Solar Control Low-E Coatings

Solar control Low-E coatings are made using the MSVD (sputtered) process. They usually have a thin coating of silver. Due to this, they have lower emissivity, which means they block most of the sun’s heat from entering homes and buildings. Solar control Low-E coatings are mainly used in hot climates to stop outdoor heat from entering the home.

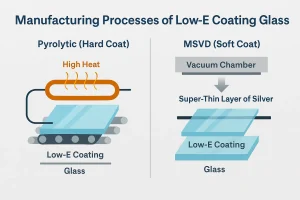

Manufacturing Processes of Low-E Coating Glass

The manufacturing of the low-emissive coating tells us which is made more durable. Let’s discuss the manufacturing process to find out how different types of low-E coatings are made!

Pyrolytic (Hard Coat)

In the pyrolytic method, the coating is applied while the glass is in the manufacturing stage. The extreme heat fuses the coating tightly with the glass. As a result, a strong bond develops between the coat and glass. Once the glass is ready, it is cut into sheets and used for windows or doors.

This process is also called a “hard coat” application. Because the coating is durable, it’s commonly used in places like storm doors and windows, where the glass needs to withstand more wear and tear.

MSVD (Soft Coat)

The MSVD process is different. In this process, the coating is applied after the glass has already been made and cut. It happens inside a vacuum chamber. Since the bond is weaker than the pyrolytic method, a seal or laminate is added for strength.

This “soft coat” method usually uses a super-thin layer of silver. It has lower emissivity. This means it blocks more of the sun’s heat. It is more delicate than a hard coat. For that reason, the soft coat is always placed on the inner surface of double or triple-pane windows, where it’s protected.

To preserve the coating and stop it from oxidizing, gases like argon or krypton are often sealed between the panes. These gases don’t just protect the coating but also improve insulation better than air.

In some designs, manufacturers even suspend a thin, transparent low-e film between two panes of glass. This insertion makes the window more effective at reflecting heat and keeping homes energy efficient.

Key Performance Measures for Low-E Coatings

Let’s discuss some key measures to check the performance of Low-E coatings.

1. U-Value

U-value is the rating given to a window based on how much heat loss it allows. A lower U-Value means better insulation.

2. Visible Light Transmittance (VLT)

Visible Light Transmittance is a measure of how much light passes through a window. Windows with a higher VLT value mean enough visible light brightens your homes and buildings without unwanted heat.

3. Solar Heat Gain Coefficient (SHGC)

The SHGC shows how much of the sun’s heat passes through the glass. A lower SHGC means less solar heat enters your home. This is great for hot climates where you want to keep interiors cooler.

4. Light-to-Solar Gain (LSG)

Light-to-Solar Gain is the ratio between the window’s Solar Heat Gain Coefficient (SHGC) and its visible light transmittance (VLT) rating. A higher LSG means you get plenty of daylight without too much heat.

Low-E coatings work by reducing ultraviolet (UV) and infrared (IR) light while allowing visible light to pass through. This balance keeps homes bright, comfortable, and energy efficient.

Watch this Video to Learn More about Low-E Glass!

FAQs about Low-E Glass

Are Low-E coatings worth it?

Yes, Low-E coatings are a smart investment. They cut energy bills in winter by keeping the heat inside. They also block excess heat in summer. Over time, the savings outweigh the cost.

Do Low-E windows make rooms dark?

No, Low-E coatings are almost invisible. They reflect heat. They also block harmful rays. But they do not block natural daylight. Your rooms stay bright. They also stay cooler and more comfortable.

Can Low-E coatings be added to old windows?

Yes, you can add Low-E films to existing windows. They are not as effective as factory-coated glass. Still, they reduce heat loss. They also block UV rays.

How long do Low-E coatings last?

Factory-applied coatings can last 20 years or more. They are sealed inside the glass. Window films last 10–15 years. Their life depends on quality and care.

Do s work in all window types?

Yes, they work in single-pane windows. They also work in double-pane windows. Double-pane Low-E glass gives the best results. It offers higher efficiency and better comfort.